4. Milling the malt

After malting and kilning and before mashing, the barley malt must be ground in a special grain mill after a certain resting period.

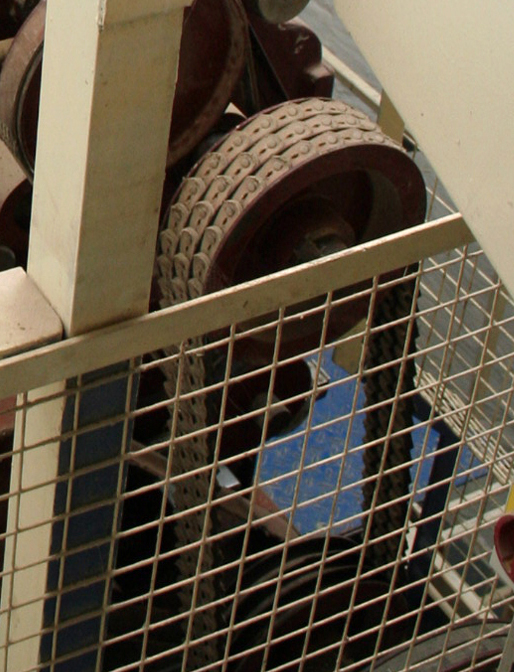

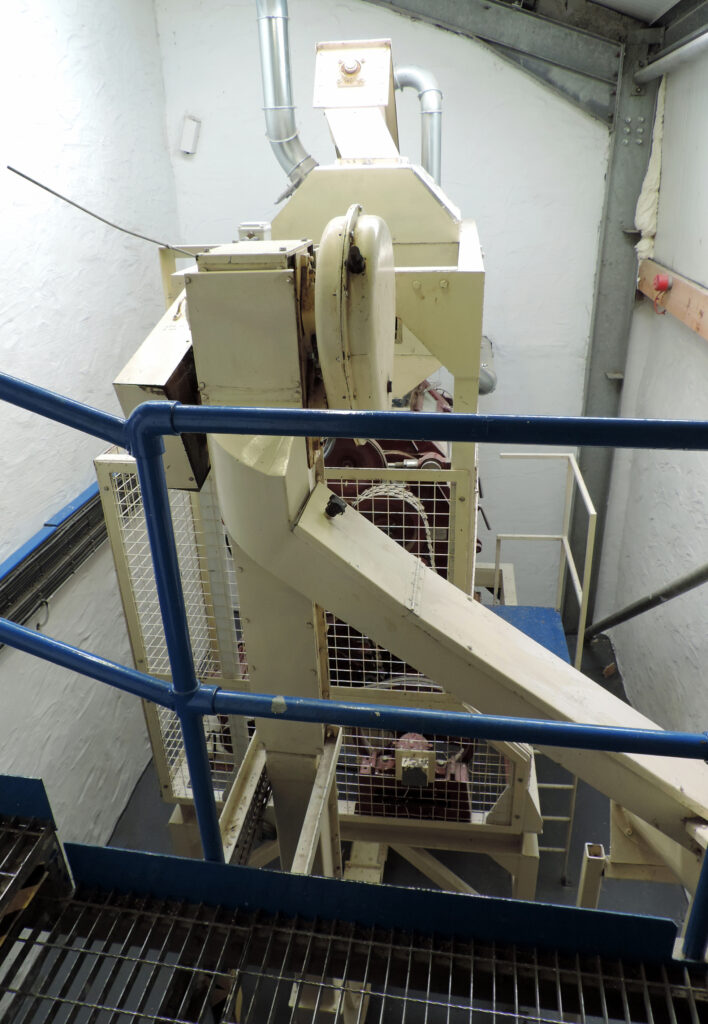

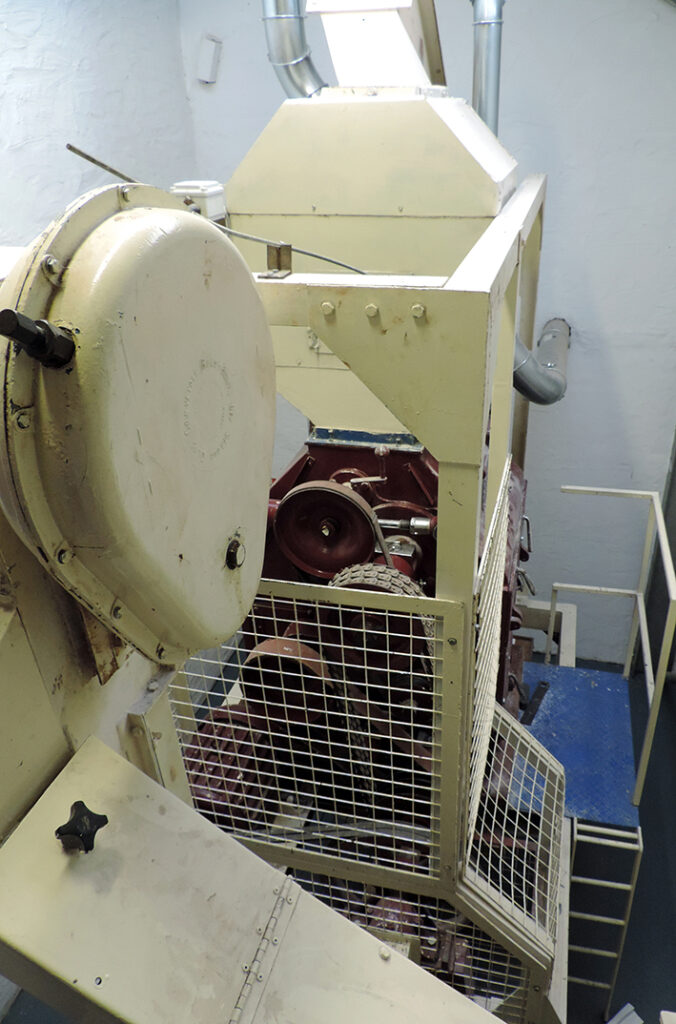

Like many Scottish distilleries, Kilchoman uses a time-honoured Porteus Mill, which was bought second-hand from a brewery in England and installed in 2005 in a small separate room behind the malting floor, to the side of the Tun Room. The Porteus Mill grinds with four metal rollers that are driven by leather belts.

One mash run requires 1.2 tonnes of malt to be ground. The milled grist should consist of 70% husk, 18% grits and 12% flour. This is constantly monitored and the rollers are adjusted in the event of deviations. The exact ratio is important in order to achieve the highest possible yield during mashing and to prevent the mash from clumping together.

.

.

.

.

.